Turn old into new: We complete the circle!

Over one million tonnes of recovered paper: This is the amount that JassPaper recycles every year. By recycling paper, we help in a variety of ways to conserve resources and make sensible use of recovered paper as a recycled material.

The recovered paper is treated to the very latest technical standards and then processed further to produce containerboard. With special grades that have very high strength values, we may add a small amount of FSC® certified (FSC-C108280) cellulose fibres.

All of our papers are FSC® certified (FSC-C108280). Our customers, the corrugated board factories, then process our flutings and liners into corrugated board sheets, which are then turned into:

- Transport packaging

- Retail packaging

- Display material

Once used, these materials are collected up again and reused as a recycled material in paper and board factories. Our papers and the corrugated board which is made from them are thus an environmentally friendly, sustainable product that can be recycled.

Many paper grades. Of the finest quality.

We produce more than one million tonnes of containerboard based on recovered paper each year. Our customers use our extensive range of paper grades to produce high-quality packaging made of corrugated board. We deliver to them in all widths from 60 to 335 cm and in grammages from 80 to 300 g/m². Our customers really appreciate this exceptionally wide range.

All from a single source, this is Jass. We are proud to be the principal supplier to many of our customers. Not least because our quality, reliability and flexibility makes us a persuasive choice.

For us, quality means

constantly monitoring the technological attributes of our papers. The look, feel and colour of the papers give them their characteristic identity and demand a suitable level of attention in production. It is not just the internal attributes but also the external features that matter: Every reel from Jass should be perfectly produced and arrive at our customers unscathed.

For us, reliability means

maintaining close contact with our customers and providing binding assurances in relation to quality, volume and delivery time.

For us, flexibility means

catering for our customers’ needs even at short notice. We are adept at handling “urgent orders”. We meet particular quality requirements and work with our customers to develop special customised grades. Tell us what you want!

Our products

Flutings / Liners

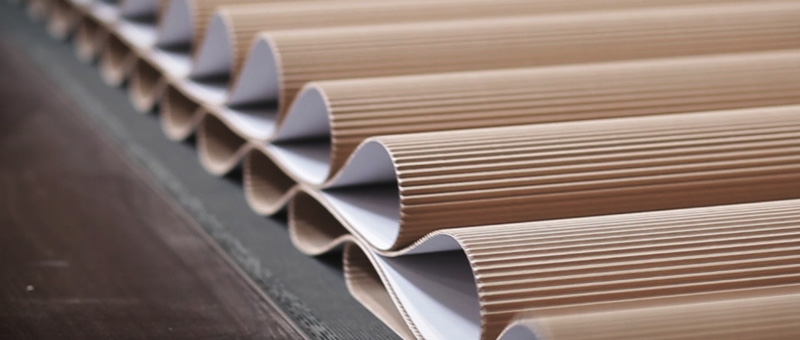

JassFlute is a corrugating medium and belongs to the group of flutings. Used as a corrugated layer between the liners, it is described by the CMT value and CST index. It gives the corrugated board its special protective qualities against external forces.

- Grammage: 80-200 g/m²

- Colour: gray

- CEPI code: 41

JassHPFlute is a high-performance corrugating medium and belongs to the group of flutings. The higher CMT and SCT index values mean that higher requirements can be met in terms of strength in comparison to simple corrugating medium.

- Grammage: 125-180 g/m²

- Colour: gray

- CEPI code: 44

JassLiner is a liner and is noted for its excellent surface strength. Characterised by the burst pressure and SCT index, we distinguish it in the classes Testliner 1, 2 and 3. Available in glued form and in an individual form to suit the customer’s wishes.

- Grammage: 90-300 g/m²

- COBB 60 sec: <40 g/m²

- Colour: brown

- CEPI code: 10/20/30

JassHiFlex is a corrugated board base paper with a dual function. The fact that the requirements for burst pressure, CMT index and SCT index are met means that it can be used both as fluting and as liner.

- Grammage: 100-150 g/m²

- COBB 60 sec: <40 g/m²

- Colour: brown

- CEPI code: 52

JassKraft belongs to the group of liners and is used as a substitute for primary fibre paper. The fact that the highest visual and technological requirements are met means that it is used primarily for highly resilient transport packaging of supreme quality.

- Grammage: 130-280 g/m²

- COBB 60 sec: <40 g/m²

- COBB 1800 sec: <135 g/m²

- Colour: brown

- CEPI code: 90

We would be delighted to discuss your individual requests with you in person and look forward to presenting our technical and technological possibilities to you. Together we will find solutions to suit your requirements!

Overview of our grammages

| JassFlute | 80 g/m² – 200 g/m² |

| JassHPFlute | 125 g/m² – 180 g/m² |

| JassLiner I brown | 125 g/m² – 200 g/m² |

| JassLiner II brown | 100 g/m² – 300 g/m² |

| JassLiner III brown | 90 g/m² – 300 g/m² |

| JassHiFlex | 100 g/m² – 150 g/m² |

| JassKraft | 125 g/m² – 300 g/m² |

Further grades are available on request.

Certificates

Our management systems are successfully audited or certified again and again every year. The certificates give us and our customers the confidence that our products and processes meet all requirements.

DIN EN ISO 9001:2015

Fulda

DIN EN ISO 14001:2015

Fulda

Fulda

ISEGA (clearance declaration)

Rudolstadt/Schwarza

“Our paper should be the best that the corrugated board industry requires.”

Adolf Jass, company founder

Paper production – technically highly complex

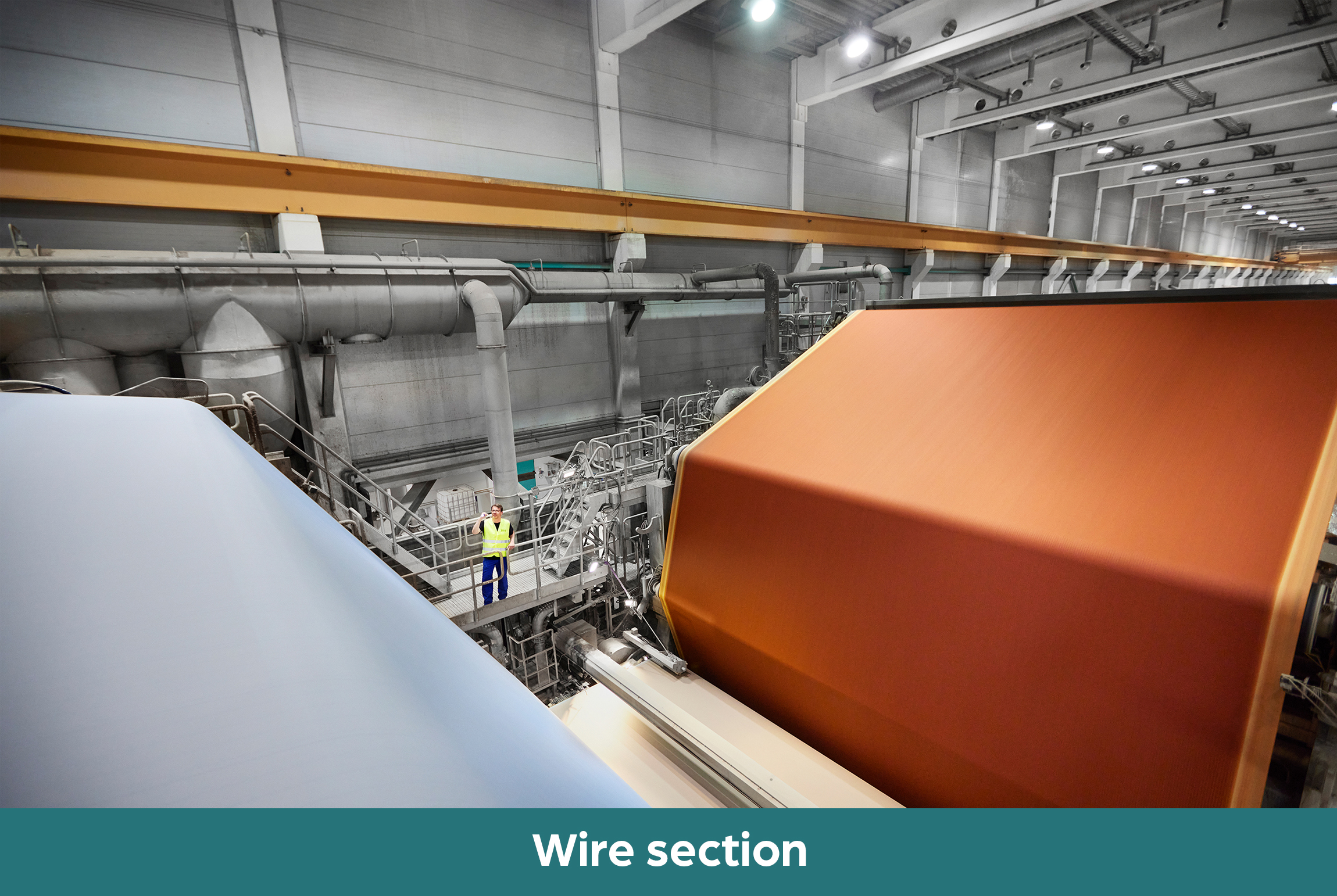

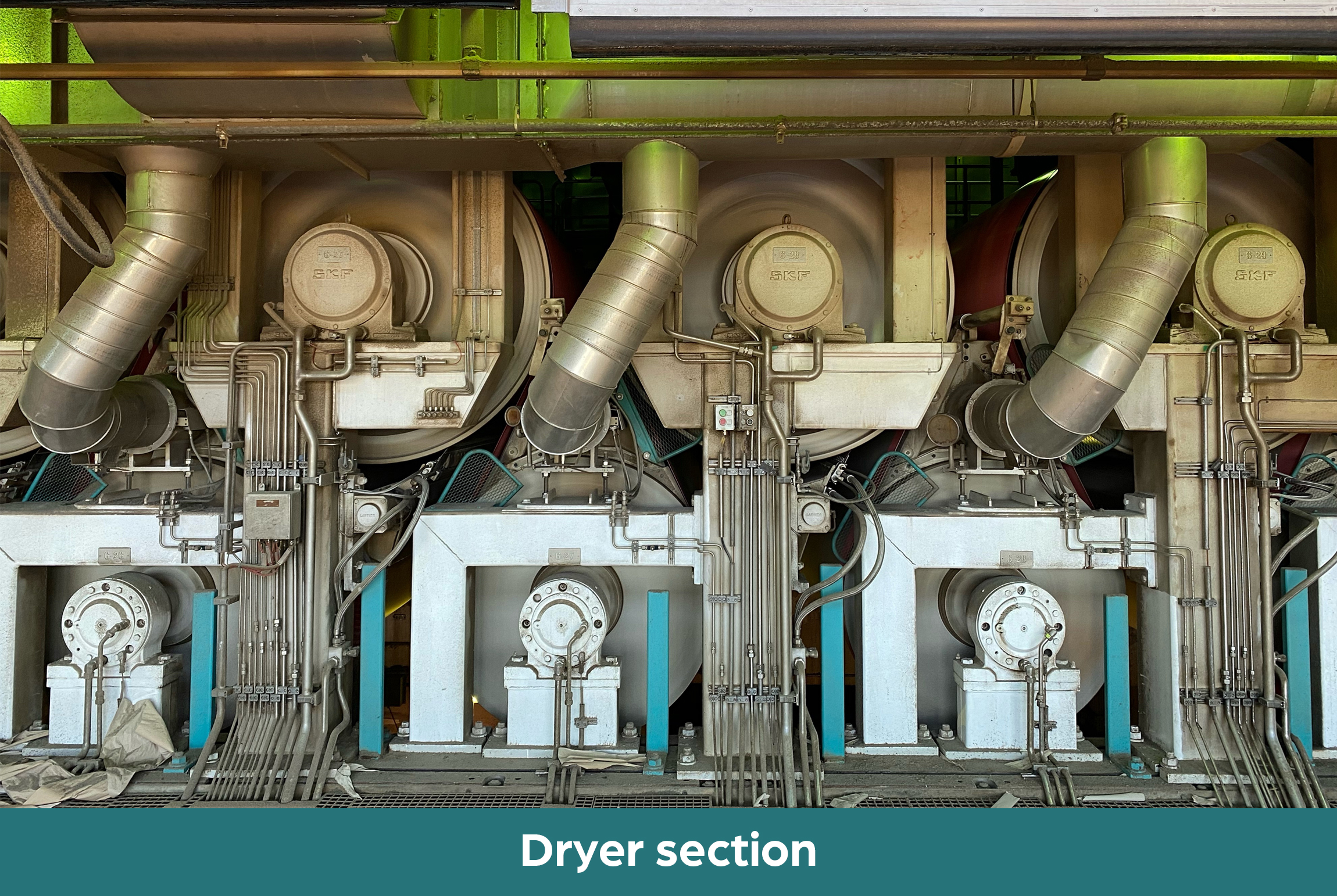

Paper-making is a fascinating, technically highly complex and very delicate process. The quality depends on the fine fibres of the raw material dissolved in water. Controlling the giant paper machines demands a watchful eye and lots of skill at all times.

The recovered paper is initially broken down with water, the fibres are separated and freed of any non-paper substances. Huge quantities of the fibre/water mixture are then sprayed onto the screen in the wire section of the paper machine. This produces the paper web. After dewatering, which takes place through the screens, the paper web passes through the press section where even more water is removed by press rolls. It then continues its journey through the hot dryer section. The paper webs, which are up to 7.5 metres wide, pass rapidly at speeds of between 800 and 1500 metres per minute over the steam-heated drying cylinders before they are finally wound as largely dry paper onto a steel core, the tambour. In the subsequent winder, the paper is rolled onto paper cores and cut to the web widths that our customers require. The reels of paper, which can weigh up to 3.6 tonnes, are stacked up to 15 metres high in a fully automatic warehouse with vacuum lifters and then await transport to the corrugated board factory.

There must be no break in this workflow – quite literally because downtimes threaten the efficiency and thus the economic viability of the production process. Modernisation work, expansion and maintenance of the machinery is a logistical feat for the whole team and everyone plays their part. It is like one big family that works together well.

Specific features of our paper machines

Paper machine 1 Rudolstadt/Schwarza (PM 1)

- Width of the paper web: 7,5 m

- Grammage of the papers: 80 – 120 g/m²

- Production capacity: 500,000 t of paper/year

Paper machine 3 Fulda (PM 3)

- Width of the paper web:

5,1 m - Grammage of the papers: 120 – 140 g/m²

- Production capacity: 300,000 t of paper/year

Paper machine 4 Fulda (PM 4)

- Width of the paper web: 5,1 m

- Grammage of the papers: 140 – 300 g/m²

- Production capacity: 300,000 t of paper/year

When a paper machine undergoes a major overhaul, almost all grades and grammages can then be produced on one of the other two paper machines. This means our customers can be confident of receiving a reliable supply.

Our paper machines are state-of-the-art because we maintain them to the very latest standard. Our annual capacity has increased from around four thousand tonnes in 1960 to today’s figure of more than one million tonnes of containerboard. Each year, our machines in combination produce a paper web long enough to be wrapped 40 times around the Earth’s equator.

Behind the scenes of paper machine 1

Paper machine 1

| Schwarza PM 1 | Weight: 6,200 t | Pipelines: 50 km | Number of pumps: 209 |

| Length: 160 m | Electrical cables: 433 km | Sensors: approx. 1,150 |

“Fantastic! This is how it feels when we start operating a new machine or an existing machine following a major refit. Everyone shares in this. It leaves an indelible mark on our collective memory. Anyone who experiences this never forgets it. And then we understand how to celebrate our successes and really do so in style!”

Dr. Marietta Jass-Teichmann, managing partner

FAQ

Important questions

01 | How can I get hold of the technical data sheets for the containerboard from Jass?

We will be happy to send you the technical data sheets for our containerboard. Please contact us about this.

02 | Who should I contact to order product samples?

We will be happy to send product samples. Please contact us about this using the contact form.

03 | Is containerboard from Jass suitable for food contact?

Jass papers meet the requirements set out in Recommendation XXXVI of the Federal Institute for Risk Assessment, Regulation (EC) No. 1935/2004, Regulation (EC) No. 2023/2006, as well as Resolution ResAP (2002) 1 and are certified for use in the food industry. Jass papers may be in direct contact with dry, non-fatty foods and those foods which are peeled or washed before being consumed, and may be used as secondary packaging. Their conformity is reviewed and certified by external laboratories.

04 | Does containerboard from Jass comply with REACH?

Jass papers meet the requirements of EU Regulation No. 1907/2006 (REACH Regulation) and EU Regulation No. 850/2004 (Persistent organic pollutants). Furthermore, Jass papers meet the requirements of the European Packaging Directive 94/62/EC. This means that the content of lead, cadmium, mercury and chromium is within the legally defined limits.

05 | Does Jass have a certified quality management system?

JassPaper is certified according to ISO 9001.

06 | Does Jass have a certified environmental management system?

JassPaper is certified according to ISO 14001.

07 | Besitzt Jass ein zertifiziertes Energiemanagementsystem?

JassPaper is certified according to ISO 50001.

08 | Does Jass have a hygiene management system?

JassPaper has a hygiene management system and a hygiene policy.

09 | What are Jass papers made from?

JassPaper is made from up to 100% recycled paper. The unbleached pulp that is used for the production of selected Jass papers originates from FSC® certified forests.

10 | Is containerboard from Jass FSC® (FSC-C108280) certified?

Jass papers are FSC® certified.

Making contact

We are there for you!

Papierfabrik Adolf Jass

36039 Fulda

T +49 0661 1 06-0

info@jass.com

Papierfabrik Adolf Jass

Rudolstadt/Schwarza

T +49 3672 4 77-0

info@jass.com

You might also be interested in these topics

JassFibre

Ever since we were founded back in 1960, we have consistently used recovered paper as a recycled resource for making paper.

Learn moreJassBoard

With a team of experts very much focused on delivering service of the highest quality, we at Convert Paper offer our cardboard and corrugated board products using a unique logistics system.

Learn more